Powerful, universal and precise: CNC 5005

The 5-axis machining center for all requirements

Modularity

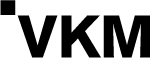

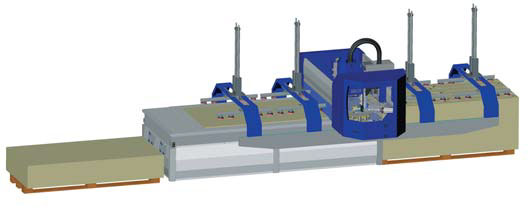

The CNC 5005 5-axis machining center opens up almost unlimited manufacturing possibilities. Due to the modularity of the CNC5005 and the extensive standard options, the machining center can be optimally adapted to customer requirements. The stable construction guarantees the highest accuracy and reproducibility of all components.

It is designed for universal use from single-part production to series production. The “Gantry” design (the gantry is driven on both sides in the x-direction) guarantees consistently optimum results even at the highest traversing speeds.

Software and Hardware

The CNC5005 is programmed with standard G-code and complies with ISO 6983 This allows the most popular 2D/3D CAD and CAM software packages to be used with ease. Digital servo amplifiers ensure less vibration and thus more accuracy. In addition, the CNC machine has a built-in USB connector that allows connection to the Internet. This means that orders can also be placed and queried from any remote location. The control panel for the CNC 5005 is mobile due to rollers and thus always ensures optimal workstation positioning.

Worktable for wooden panels

The working area offers individual designs between 2500/4750/8000 mm (x-axis) x 1540/2050 mm (y-axis) x 200 mm (z-axis). The vacuum table is divided into 8 sections, each section is controlled by its own valve. In each section, there are 8 vacuum cups, which ensure a firm hold during the working process. In addition, dedicated stop suckers ensure a more precise positioning of the workpiece. If you also combine the vacuum table with special suction pads, better edge processing is also ensured.

Milling spindle

An 11 or 12 kW spindle motor with ceramic bearing with a tool changer is supplied as standard, providing for ISO30 and HSK63 tool holding. The spindle is driven by a frequency converter which, with a speed range of 300-24000 rpm, leaves nothing to be desired in terms of efficient working speed.

Special equipment on request

You have a choice when it comes to the drill head, the exact size, type and number of fixtures you want. With a multiple drilling head, for example, 7 to 25 holes can be drilled simultaneously. Each drill is controlled individually. An angular head in turn ensures perfect cutting, drilling, and turning with horizontal spindle.

With a 4-axis turning device, parts can also be machined on the circumference.

The CNC 5005 machining center can be equipped with a loading and unloading device optimized for the process to increase throughput and safely handle large and bulky parts.

A specially installed laser can project the correct positioning for the parts to be produced onto the worktop in advance.

Beyond all the equipment, the CNC 5005 machining center thus offers you maximum modularity with highly satisfactory, fully automatic use.

Technical data:

Field

| x-axis | 2500mm | 4750mm | 8000mm | |

| y-axis | 1300mm | 1540mm | 2050mm | |

| z-axis | 200mm | 400mm | 600mm |

Travel speeds

x-axis 60m/min

y-axis 20m/min

z-axis 15m/min

c -axis 360°

B-axis 220°

You are interested in a CNC 5005 machine?